Free Wheel Hub Buyer's Guide

Buying a free wheel hub for your car can sometimes be a daunting and confusing task. At maxpeedingrods.com, it is our mission to make that task as an easy and painless as possible. This Buyer's Guide is designed to answer any questions you may have during your search for the right free wheel hub for your car, and how to buy free wheel hub on our website.

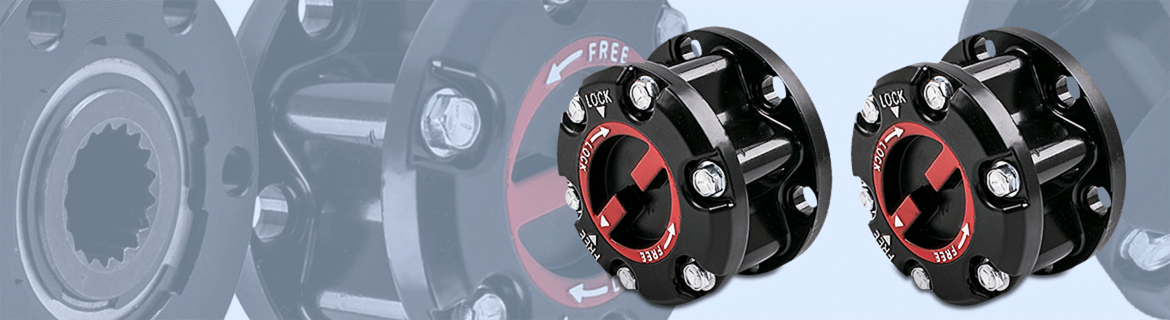

What is a free wheel hub?

A wheel hub is the axle and bearing mechanism around which the wheel revolves. It is the mounting assembly for the wheel of a vehicle and houses the wheel bearings. Some vehicles will also have the speed sensor attached to the wheel hub assembly, which will be attached with an electrical connector. A full wheel hub assembly in most cases will include the wheel hub unit, the bearings, seals and sensors. Without the wheel hub, your vehicle will not turn as freely as it should, and handling would be extremely difficult.

How do free wheel hubs work?

Free wheeling hubs or Locking Hubs engage or disengage the front half shaft (drive shaft) from the hub

of the front wheels. This allows the 4WD to behave in the same fashion as a conventional two wheel drive

car with only the rear wheels being 'driven'. It is only when 4WD is selected and the hubs set in the

'locked' position that the vehicle operates as a four wheel drive - with power being applied to all

wheels.

The free wheeling or locking hub contain a spring loaded collar that slides inwards and meshes with the

front half shaft when the actuator is set to 'Lock'. When the actuator is set to 'Free' the front wheel

spins independently of the front drive shafts and differential and the car is virtually a 2WD. When the

actuator is set to 'Lock' the front wheels, drive shaft and differential are coupled as one unit. Once

the transfer case has been engaged and High 4x4 or Low 4x4 selected then the car is operating in

4WD.

Selecting 4WD in a car fitted with free wheeling hubs involves two separate actions. The hubs must be

'locked' and the transfer case must be engaged to either H4x4 or L4x4. If 4x4 has been selected inside

the car and the hubs are still in the free position the front differential and drive shafts are turning

and being 'driven' but the car is still in 2WD because the hubs have not been coupled with the rest of

the drive train.

It makes no difference which action occurs first - locking the hubs or engaging four wheel drive.

How to buy free wheel hub?

Selecting a free wheel hub is never an easy thing unless you get to know these things nicely.

You can find your free wheel hub by entering your vehicle's year, make and model, If for any reason you

cannot , you can find it by its Original Equipment Manufacturer (OEM) number. The OEM part number can be

found directly on the part itself. You can also call a dealership with your VIN, and they will provide

you with the OEM part number. You can contact one of our car specialists

through our website for further assistance on how to buy a free wheel hub.

Why buy free wheel hub at MaXpeedingRods?

MaXpeedingRods has been engaged in the research of overseas racing products and culture for

decades. If you are looking for free wheel hub, you have landed at the right place. On the basis

of your vehicle make and model, you can choose from a plethora of automotive maintenance and

accessories. MaXpeedingRods offers a seamless online shopping experience and the streamlined

e-commerce interface makes it easy for you to find just the free wheel hub you want.

MaXpeedingRods offers a variety of free wheel hubs with high quality.

What are the symptoms of a bad or failing wheel hub assembly?

The wheel hub assembly is prone to damage caused by multiple driving situations such as:

• Hitting pot holes

• Striking cubs

• Being involved in vehicle collisions

Although this part takes a tremendous amount of abuse, it's commonly overlooked when repairs are done to

other mechanical components such as tires and wheels, suspension parts, coils, shocks and struts and

other front end and rear end housing parts. When the part is damaged or is beginning to show signs of

premature wear, it will commonly show some warning signs or symptoms that can be easily recognized by

most car owners.

Listed below are a few of the symptoms that you should be aware, that will alert you to a bad or failing

wheel hub assembly.

Typically when a wheel hub assembly goes bad it's actually the wheel bearing inside the single assembly that is damaged. This part will make a roaring sound, similar to a metal-to-metal grinding sound when the bearing is wearing out. This sound is caused by lack of lubrication inside the bearing, a misaligned bearing or one that has cracked due to impact with another object. It's very difficult to determine by sound which wheel bearing is going bad as the sound can be very misleading. However, if one side wheel hub assembly is broken, both sides on the same axle need to be replaced at the same time. If you notice any roaring or grinding sound coming from the front end of your vehicle, safely drive home and contact a local ASE certified mechanic as soon as possible.

2. Steering wheel vibrates or feels looseAnother indication of a damaged wheel hub assembly is when the steering wheel vibrates at lower speeds and progressively gets worse as the car accelerates. A damaged wheel hub assembly can also cause the steering wheel to feel loose when you're driving down the road, making turns or negotiating dips in the road. The reason for this is commonly due to a worn out wheel bearing inside the hub assembly. If you notice this symptom, it's recommended to contact a certified mechanic as soon as possible so they can road test your vehicle. This is often the best way to properly diagnose what is actually causing the vibration in the steering wheel, and can save you a lot of time and money on replacing the wheel hub assembly.

3. Tire / wheel combination has a lot of play when in the airMost of the time this symptom will be noticed by a certified tire mechanic, brakes replacement service, or oil change center that is rotating your tires. When the vehicle is on a hydraulic lift or on jack stands, and the tire / wheel combo is tightly attached to the wheel hub assembly, but wiggles from left to right or up and down when pulled, this is an indication of a broken wheel hub assembly and should be replaced immediately. Once again, broken wheel hub assemblies should be replaced in pairs on the same axle.

4. Clicking sound from the wheels

Finally, if you hear a clicking sound that increases in speed as the vehicle accelerates, this could

be a problem with the wheel hub assembly as well. In this case, the brake caliper will move up and

down and hit the top of the wheels as the vehicle drives down the street. This is due to the wheel

hub assembly bearing being broken.

If you notice any of the above warning signs, please contact a local ASE certified mechanic as

quickly as possible so they can diagnose the precise problem and fix your vehicle as quickly as

possible.

How to install a free wheel hub in a car?

A wheel hub assembly is a vital part on a vehicle, particularly in regards to how the vehicle feels while driving and how it handles. These assemblies are exactly the same as a normal wheel bearing and hub, except they can be changed out by just removing a few bolts. This makes it a maintenance item, which means it is much easier to replace when the time comes. When the wheel hub assembly is failing, you will notice a screeching sound coming from the wheel and loose steering.

Step 1: Prepare your work area.Make sure the vehicle is on a level, safe surface, and you have set the parking brake.

Step 2: Loosen the lug nuts.Use a ½ inch drive breaker bar and a lug nut socket set to loosen all the lug nuts and axle nuts (if applicable) before you jack the vehicle up in the air.

Step 3: Jack the vehicle up and use jack stands.Jack your vehicle up and put it on jack stands. Place the wheels off to the side, away from the work area. Be sure to jack the vehicle up in the correct location; usually on the sides underneath there are pinch welds you can use to jack from. Then make sure you place the stands on the body or frame and lower it down onto the stands.

Step 4: Remove the old wheel hub assembly.Remove the axle nut if there is one on the vehicle. Then start disassembling the brakes by removing the caliper bolts and the bracket bolts. Next, remove the rotor. If the vehicle has anti-lock brakes, disconnect any wiring harness plugs. Loosen all the bolts that hold the wheel hub assembly onto the knuckle. Once that is done, you should be able to remove the wheel hub assembly as a unit.

Step 5: Install the new wheel hub assembly and brake parts.Work in the reverse order of the way you removed everything. Start by bolting the new wheel hub assembly to the knuckle and connecting the ABS sensor connector if there was one. Next, torque the bolts to specs, which can be found online or in the vehicle's service manual. Install the rotor back onto the hub and start reassembling the brakes. Install the brake bracket back to the knuckle, Torque it, then install the pads and the caliper back onto the bracket and reinstall the axle nut (if applicable).

Step 6: Reinstall the wheels.Place the wheels back onto the hubs using the lug nuts. Snug them all down with a ratchet and socket.

Step 7: Jack the vehicle back off of the jack stands.Grab the jack, place it in the correct spot under the vehicle, and jack the car up until you can remove the jack stands. Then you can lower the vehicle back onto the ground.

Step 8: Torque the wheels.Most cars use a torque from 80 ft lbs to 100 ft lbs. SUVs and trucks usually use anywhere from 90 ft lbs to 120 ft lbs. Use a ½ inch torque wrench and torque the lug nuts to the proper specification.

Step 9: Test drive the vehicle.Since you had the brakes apart, make sure you pump the brake pedal a few times so the pads can reseat to the rotor. When test driving, make sure that you no longer have any noise coming from the hub bearing. If you do not hear anything then you can consider this job done. This job can be accomplished with the right tools and knowledge, but there are quite a few parts and bolts to be removed and put back together.